Introduction

Heating, ventilation, and air conditioning (HVAC) systems are essential for maintaining a comfortable and healthy indoor environment in residential, commercial, and industrial buildings. These systems rely on various components to function efficiently, and one of the most critical elements is the power cable. Power cables are responsible for delivering electricity to the HVAC system, ensuring that it operates smoothly and effectively. In this comprehensive guide, we will explore the importance of power cables for HVAC systems, discuss the different types of cables available, and provide tips for selecting and installing the right cable for your needs.

Importance of Power Cables for HVAC Systems

Power cables play a crucial role in the operation of HVAC systems. These cables are responsible for delivering electrical power from the main power source to the various components of the HVAC system, such as the compressor, blower motor, and control panel. Without a reliable and properly sized power cable, the HVAC system may not function efficiently or may even fail to operate altogether.

In addition to delivering power, power cables also ensure the safety of the HVAC system and the building occupants. Properly installed and insulated power cables help prevent electrical hazards, such as short circuits, electrical fires, and electrocution. Ensuring that the power cables are of high quality and suitable for the specific requirements of the HVAC system is essential for maintaining the safety and reliability of the system.

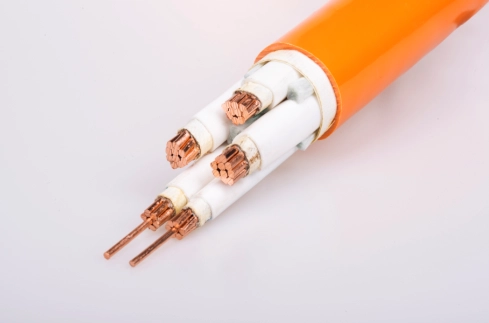

Types of Power Cables for HVAC Systems

There are several types of power cables that are commonly used in HVAC systems, each with its own characteristics and applications. Rubber Sheathed Cable of power cables used in HVAC systems include:

1. Non-Metallic Sheathed Cable (NM)

2. Armored Cable (AC)

3. Metal-Clad Cable (MC)

4. Flexible Metal Conduit (FMC)

5. Liquid-Tight Flexible Metal Conduit (LFMC)

Non-Metallic Sheathed Cable (NM): NM cable, also known as Romex cable, is a type of power cable that consists of two or more insulated conductors enclosed in a plastic sheath. NM cable is commonly used in residential HVAC systems for wiring outlets, switches, and lighting fixtures. It is easy to install and relatively inexpensive, making it a popular choice for residential applications.

Armored Cable (AC): Armored cable, also known as BX cable, is a type of power cable that consists of insulated conductors encased in a flexible metal armor. AC cable provides better protection against physical damage and is often used in commercial and industrial HVAC systems where the cable may be exposed to mechanical stress or environmental hazards.

Metal-Clad Cable (MC): MC cable is similar to AC cable but has an additional metal jacket for enhanced protection. MC cable is commonly used in outdoor HVAC applications or in areas where the cable may be exposed to moisture or corrosive substances. The metal jacket provides extra protection against physical damage and helps prevent electrical faults.

Flexible Metal Conduit (FMC): FMC is a type of power cable that consists of a flexible metal conduit with insulated conductors inside. FMC is commonly used in HVAC systems where flexibility is required, such as in tight spaces or areas with frequent movement. FMC is easy to install and provides good protection against physical damage and environmental factors.

Liquid-Tight Flexible Metal Conduit (LFMC): LFMC is similar to FMC but has a liquid-tight jacket that provides additional protection against moisture and water ingress. LFMC is commonly used in outdoor HVAC applications or in areas where the cable may be exposed to water or other liquids. The liquid-tight jacket helps prevent corrosion and ensures the long-term reliability of the cable.

Selecting the Right Power Cable for HVAC Systems

When selecting a power cable for an HVAC system, several factors should be taken into consideration to ensure optimal performance and safety. Some of the key factors to consider when choosing a power cable include:

1. Electrical Load: The electrical load of the HVAC system, including the power requirements of the compressor, blower motor, and other components, will determine the size and rating of the power cable required. It is essential to select a cable with the appropriate ampacity and voltage rating to ensure safe and reliable operation.

2. Environmental Conditions: The environmental conditions in which the power cable will be installed, such as temperature, moisture, and exposure to chemicals or physical damage, will influence the type of cable needed. For example, in outdoor HVAC applications or areas with high humidity, a cable with moisture-resistant insulation may be required.

3. Installation Requirements: The installation requirements of the HVAC system, such as the length of the cable run, the presence of conduit or raceways, and the need for flexibility, will impact the type of cable selected. It is essential to choose a cable that meets the installation requirements and provides ease of installation and maintenance.

4. Code Compliance: Compliance with local building codes and regulations is essential when selecting a power cable for an HVAC system. It is important to choose a cable that meets the relevant safety and performance standards to ensure the system's compliance with the law and to prevent potential hazards.

Installing Power Cables for HVAC Systems

Proper installation of power cables is crucial for the safe and efficient operation of an HVAC system. The following tips can help ensure a successful installation of power cables in an HVAC system:

1. Plan the Installation: Before installing the power cable, carefully plan the layout and routing of the cable to ensure that it meets the system's requirements and complies with local codes. Consider factors such as cable length, bending radius, and separation from other cables or equipment.

2. Use Proper Tools and Equipment: Use the appropriate tools and equipment for cutting, stripping, and terminating the power cable. Ensure that all tools are in good condition and suitable for the type of cable being installed to prevent damage or injury.

3. Secure the Cable: Secure the power cable properly using approved cable supports, straps, or clamps to prevent sagging, kinking, or damage. Maintain the recommended spacing between cables and avoid running the cable near heat sources or sharp edges.

4. Terminate the Cable Correctly: Follow the manufacturer's instructions for terminating the power cable, including stripping the insulation, making the connections, and securing the terminals. Use proper connectors, terminals, and cable glands to ensure a secure and reliable connection.

5. Test the Installation: After installing the power cable, test the continuity, insulation resistance, and voltage drop to verify that the installation is correct and safe. Perform a final inspection to check for any defects, damage, or code violations.

Conclusion

Power cables are an essential component of HVAC systems, providing the electrical power needed to operate the various components of the system. Selecting the right power cable for an HVAC system is crucial for ensuring safe and reliable operation, as well as compliance with building codes and regulations. By understanding the different types of power cables available, considering key factors when selecting a cable, and following best practices for installation, building owners and HVAC professionals can ensure the optimal performance and longevity of their HVAC systems. Proper installation and maintenance of power cables are essential for the safety and efficiency of HVAC systems, making them a critical component of any building's infrastructure.